Cutter Diaphragm Wall

Cutter Diaphragm Wall

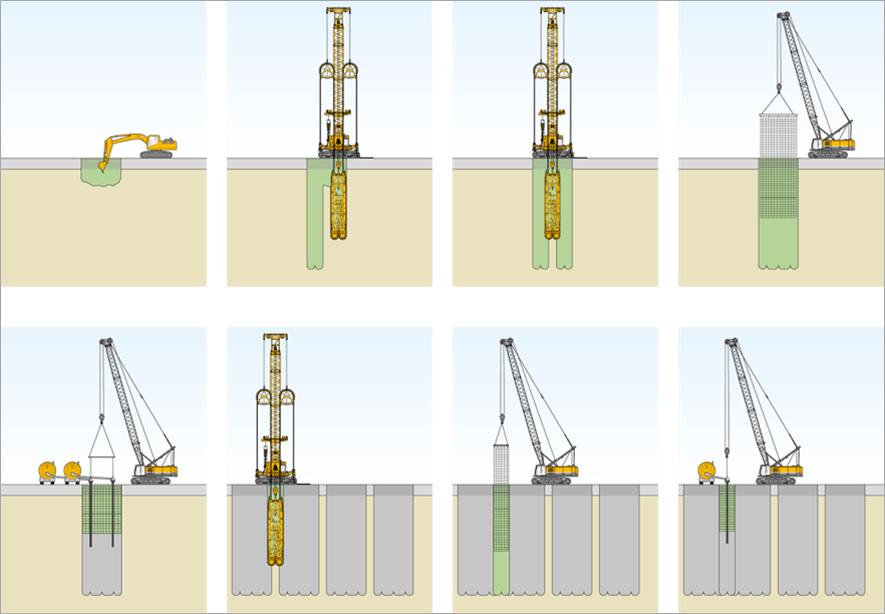

Since its introduction in 1984, the cutter diaphragm walling technique using the BAUER Cutter (BC) has developed rapidly. As a result of the wealth of experience accumulated over the following decades, the challenge being faced today is cutting trenches into extremely hard rock and achieving ever-increasing depths. Through project-specific adaptations of the cutter wheels, high excavation outputs can frequently be achieved. The open trench which is stabilized and supported by a thixotropic slurry is excavated in a continuous operation.

The slurry charged with spoil material is conveyed to the surface by a mud pump, which is mounted inside the cutter frame. The charged slurry then passes through a desanding plant. Here, the solid particles are separated out from the support slurry. The cleaned slurry is then pumped back into the slurry circulation system for reuse as support slurry in the trench. With the cutter technique depths of more than 100 m can be achieved